WHERE FAILURE IS NOT AN OPTION

The Unforgiving Nature of Cryogenic Service

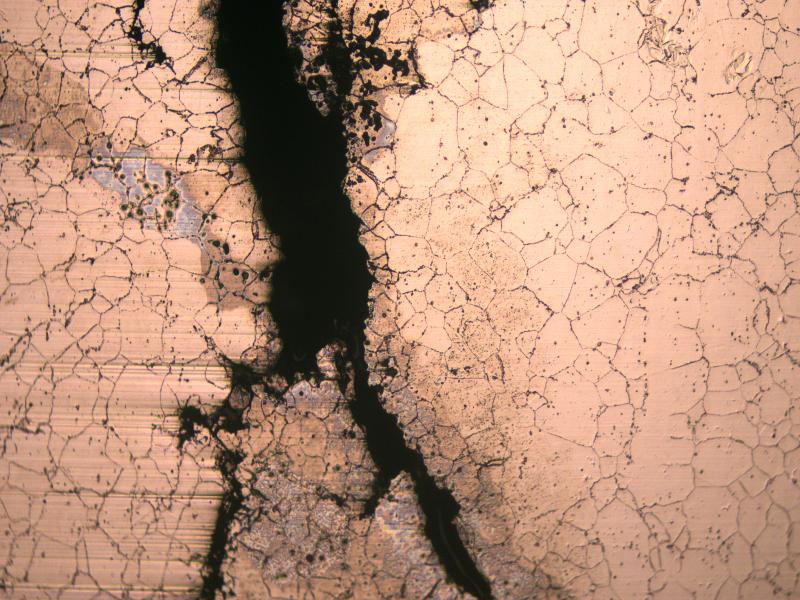

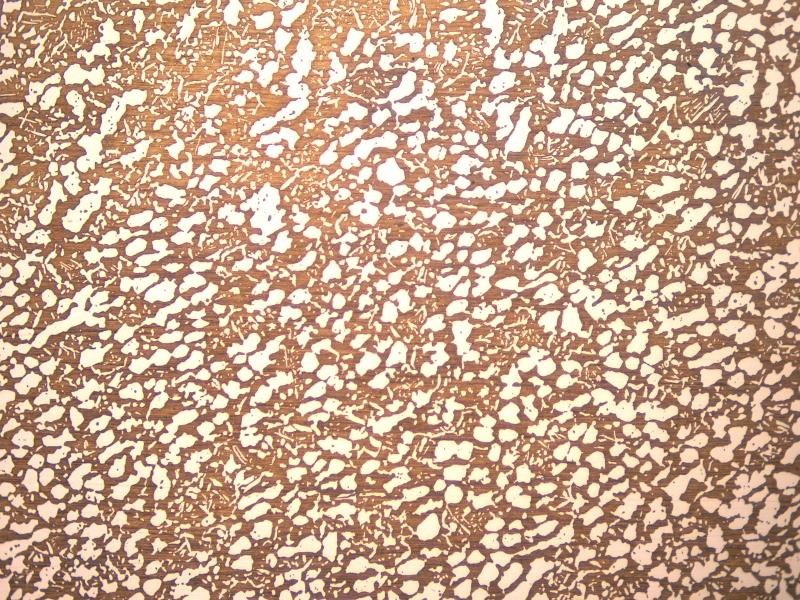

Material Embrittlement

At cryogenic temperatures, conventional metals lose ductility and can fracture catastrophically under pressure or impact, leading to critical asset failure.

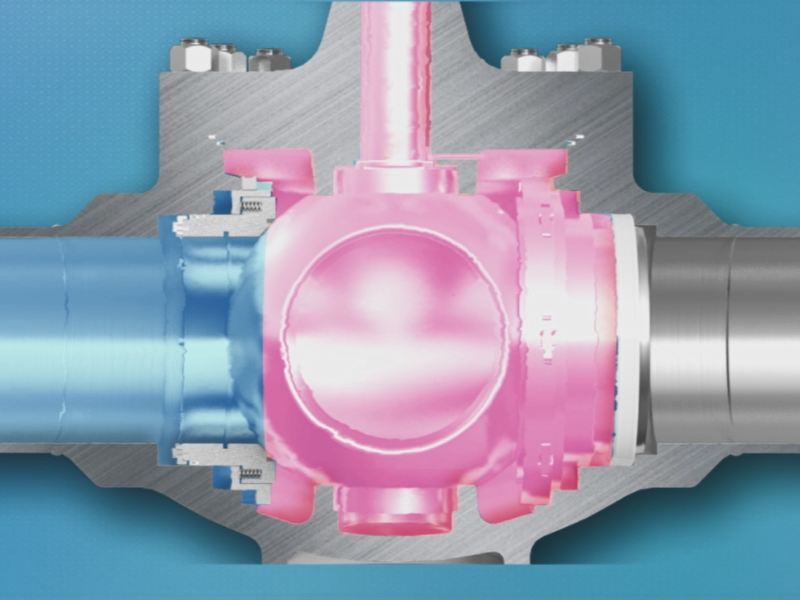

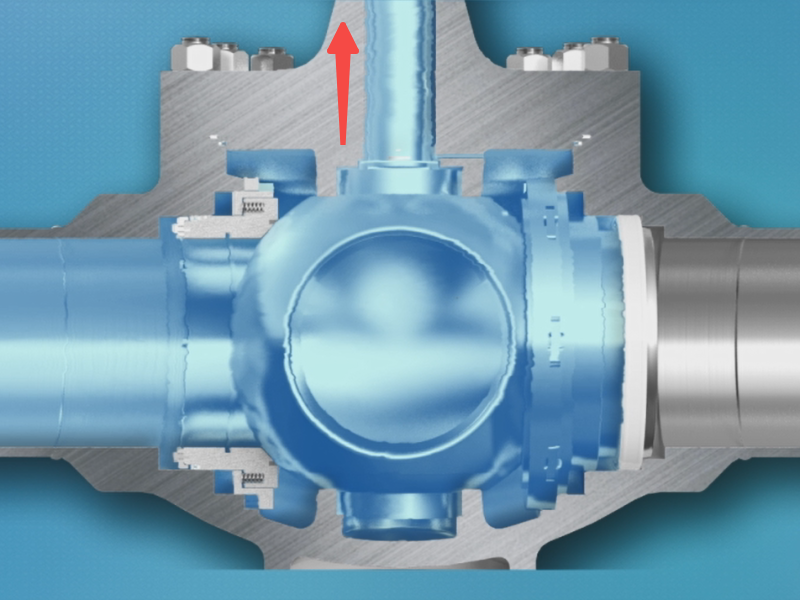

Trapped Fluid Expansion

Residual liquid trapped in valve cavities can rapidly expand when warming, creating immense internal pressure that may lead to body rupture and hazardous leaks.

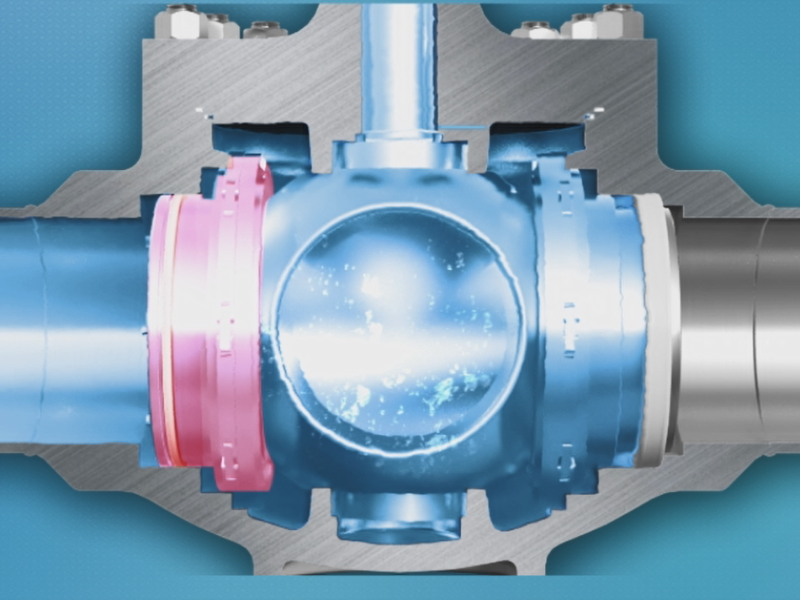

Critical Seal Failure

Extreme thermal contraction causes typical sealing materials to shrink and harden, compromising their integrity and resulting in dangerous leakage.

Valve Stem Freezing

Ice buildup from atmospheric moisture can seize the valve stem, rendering the valve inoperable and hindering critical process control and emergency response. Additionally, the freezing of packing also causes fugitive emissions.

How We Engineer to Conquer the Cold

Every Neway cryogenic valve is a synthesis of advanced design, material science, and rigorous testing, built to deliver uncompromising safety and performance.

Advanced Cryogenic Material Science

To prevent embrittlement, we use specialized austenitic stainless steels qualified by in-house Charpy impact testing at -196°C. This guarantees every component exceeds global standards for toughness and ductility.

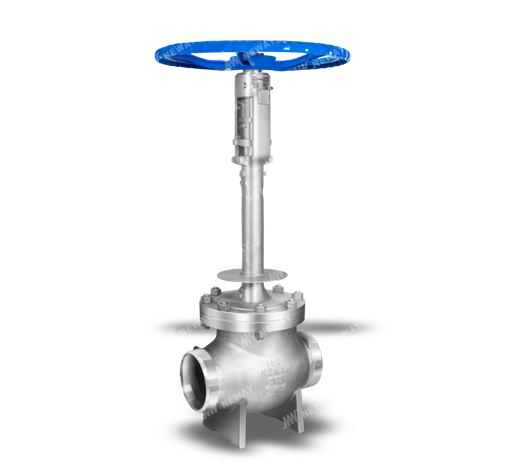

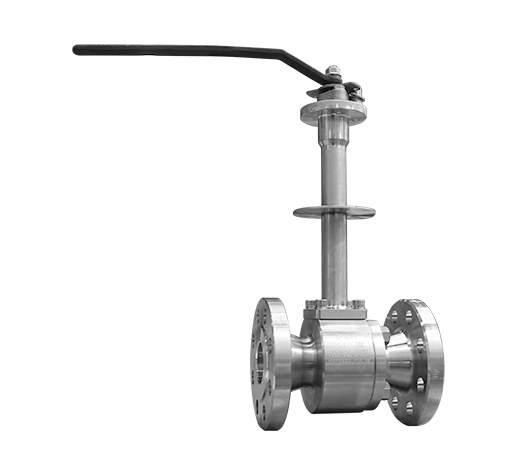

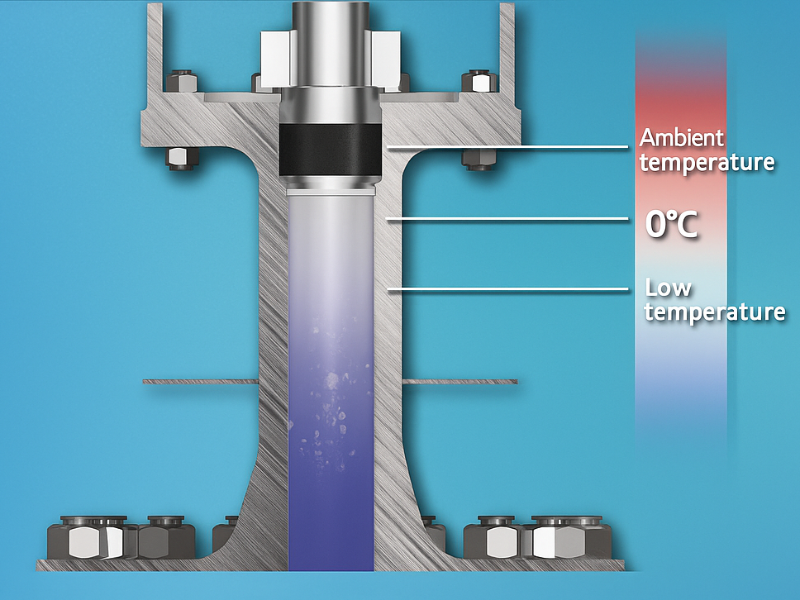

Signature Extended Bonnet Design

Our signature extended bonnet isolates the stem packing from cryogenic temperatures via an insulating vapor column. This design prevents stem freezing, ensuring continuous smooth operation and a reliable seal.

Specialized Low-Temp Sealing

Our lip-seal design utilizes materials like PTFE that remain flexible at -196°C. It operates on the principle of actively compensating for thermal contraction, with its performance verified by helium leak testing.

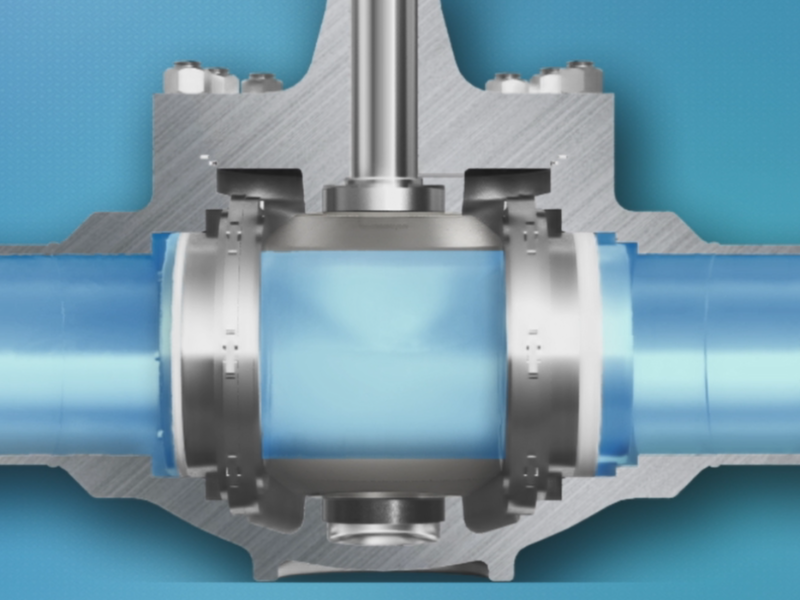

Integrated Overpressure Protection

An integrated pressure-balancing hole or a dedicated cavity relief system automatically vents pressure from trapped fluid expansion. This critical safety feature prevents catastrophic body rupture.

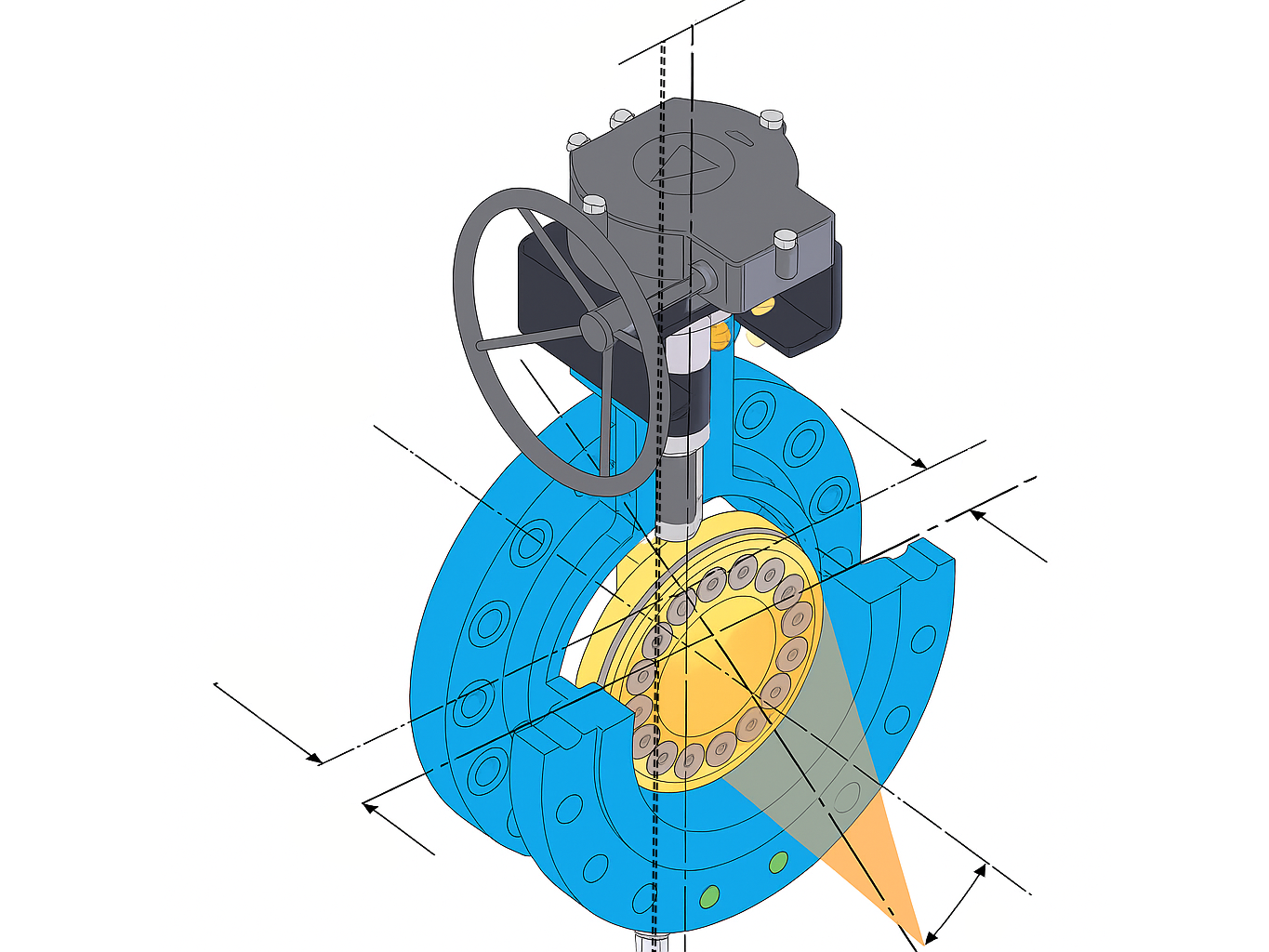

High-Performance Triple Offset Geometry

The triple offset geometry provides a friction-free, cam-like seating action. This eliminates seal wear and ensures a repeatable, bubble-tight shutoff, delivering superior reliability for large-diameter cryogenic butterfly valves.

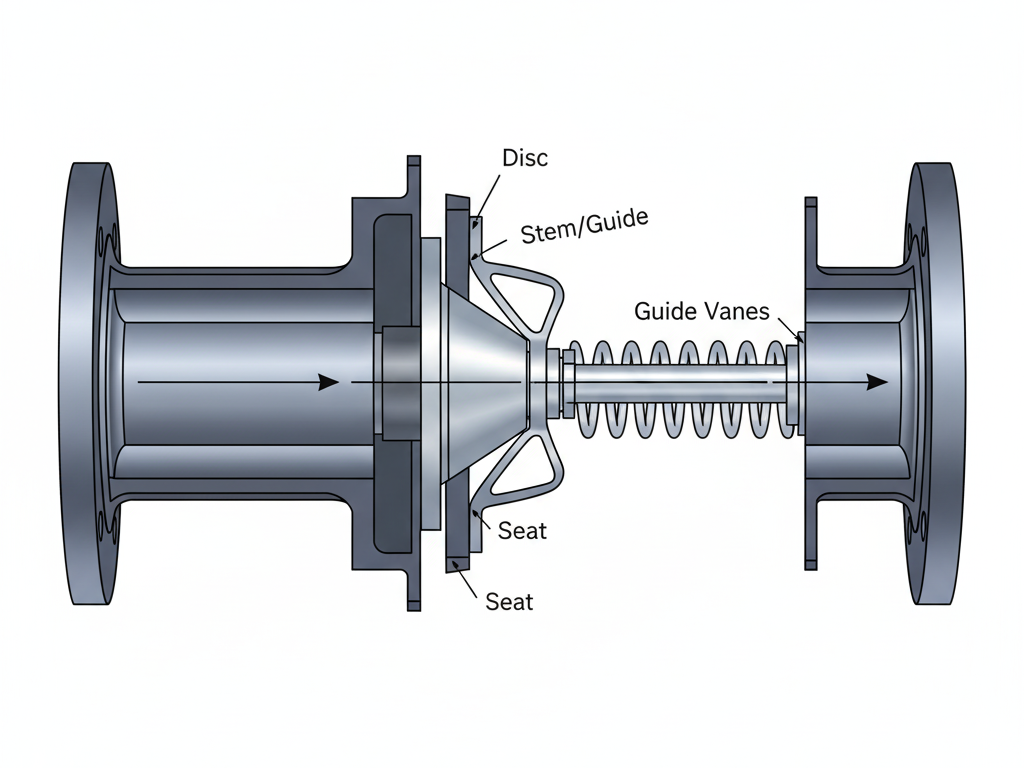

Non-Slam Axial Flow Dynamics

The spring-assisted axial check valve provides rapid, non-slam closure to prevent damaging pressure surges. This design protects pumps and upstream equipment from cryogenic shock while maintaining a low-pressure-drop, linear flow path.

TRUSTED ACROSS INDUSTRIES

Proven Reliability in Demanding Applications

LNG (Liquefied Natural Gas)

Providing critical valve solutions for the entire LNG value chain, from liquefaction and transport to regasification terminals.

Air Separation

Ensuring the safe and efficient handling of industrial gases like LOX, LIN, and LAR in air separation units and cold boxes.

Petrochemical

Delivering reliable flow control for low-temperature processes including Ethylene, Propylene, and LPG production.

Aerospace & Research

Trusted in high-stakes applications including rocket propellant systems, advanced test stands, and scientific research facilities.

FUNCTION-DRIVEN SOLUTIONS

Valves for Your Critical Process Functions

Select a process function below to find the ideal Neway valve solution for your specific application.

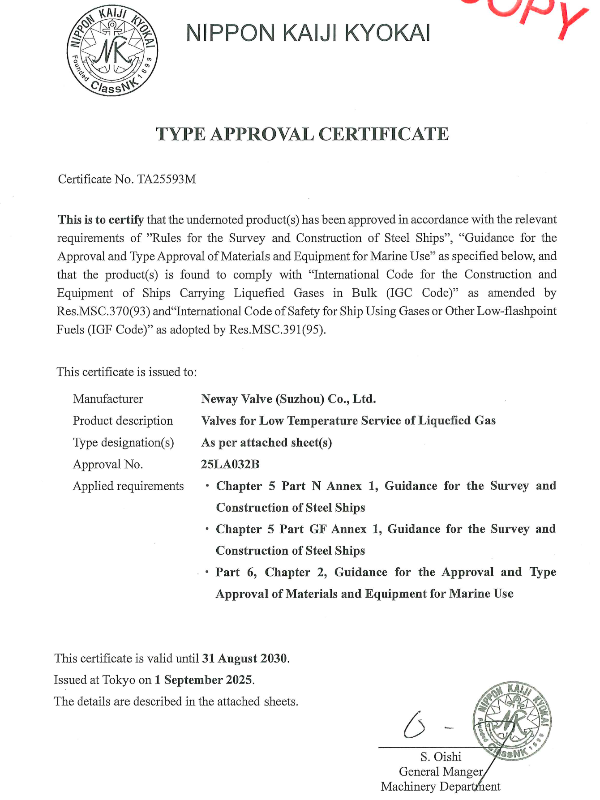

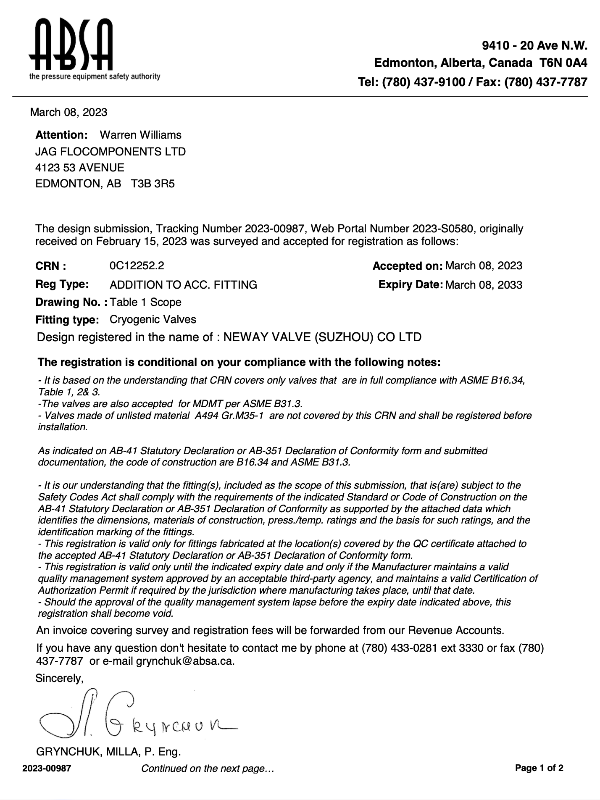

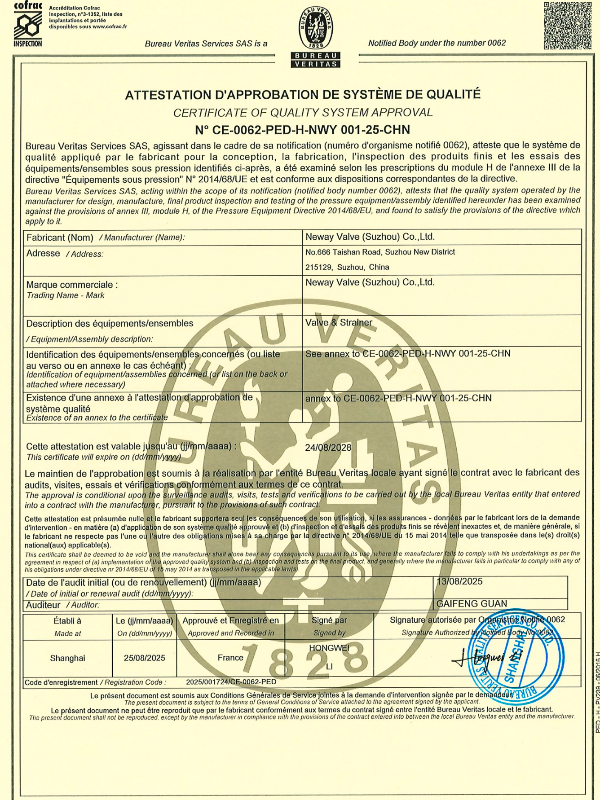

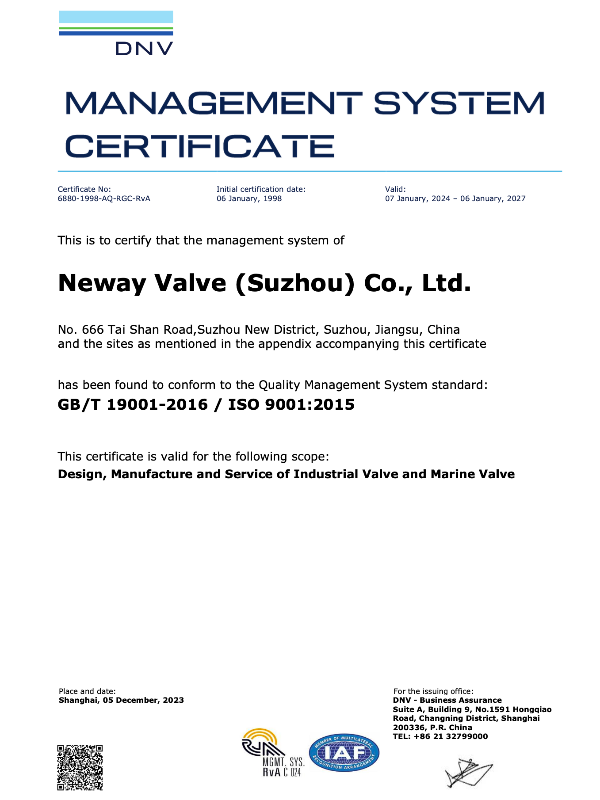

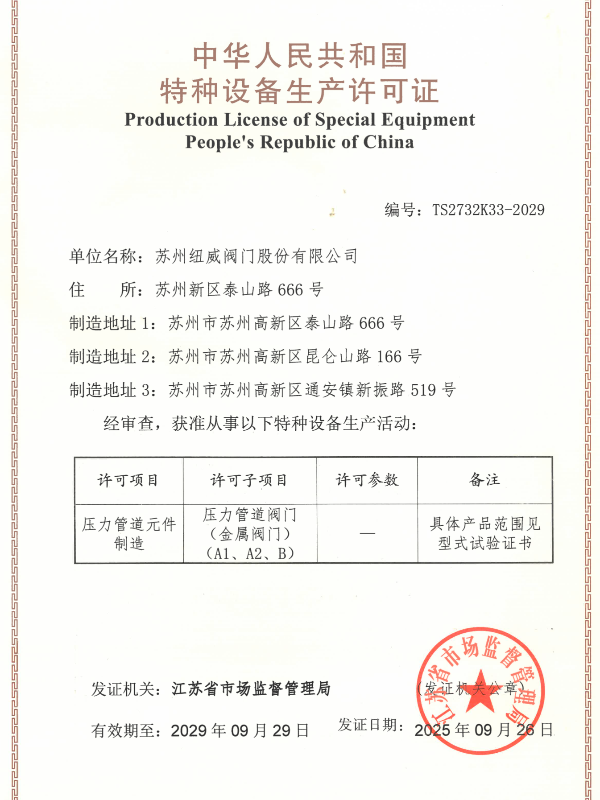

GLOBAL STANDARDS, PROVEN PERFORMANCE

Certified Quality, Tested Reliability

Our commitment to excellence is validated by the world's most stringent industry standards and proven in mission-critical projects globally.